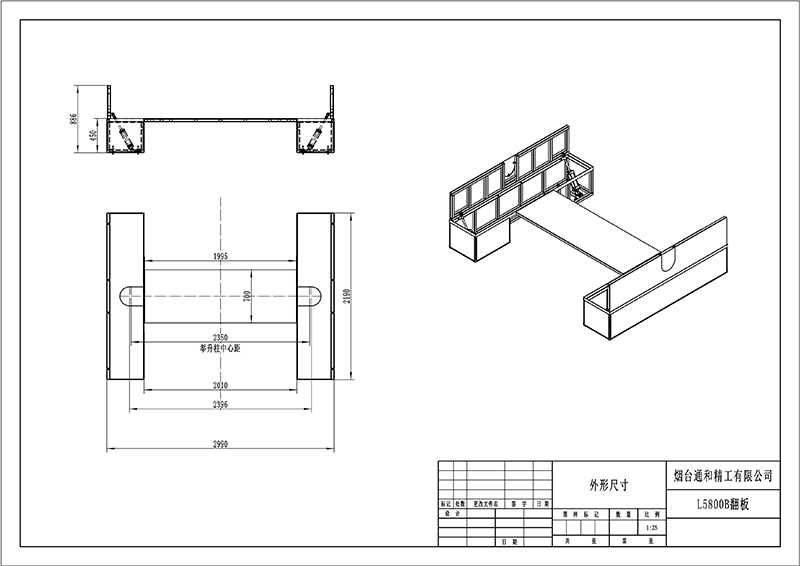

Manufacturer for Double Post Underground Lift - Double post inground lift series L5800(B) – Tonghe

Manufacturer for Double Post Underground Lift - Double post inground lift series L5800(B) – Tonghe Detail:

Product Introduction

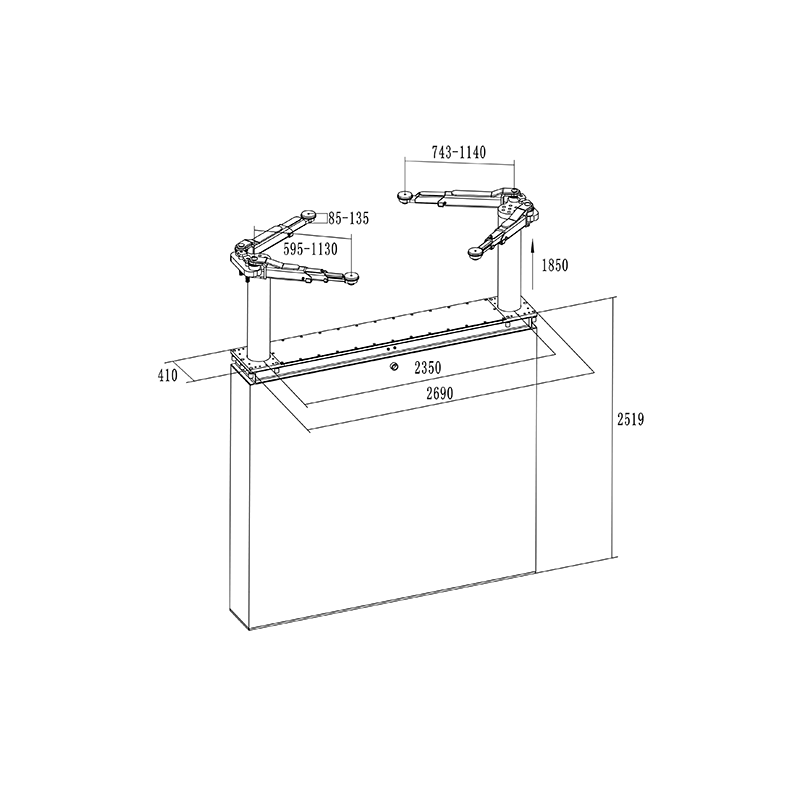

LUXMAIN double post inground lift is driven by electro-hydraulic. The main unit is completely hidden under the ground, and the supporting arm and power unit are on the ground. After the vehicle is lifted, the space at the bottom, at hand and above the vehicle is completely open, and the man-machine environment is good.This fully saves space, makes work more convenient and efficient, and the workshop environment is clean and safe. Suitable for vehicle mechanics.

Product Description

Suitable for car maintenance, car performance testing, DIY.

The whole machine adopts program control, full electric hydraulic drive, the main unit and the supporting arm are completely sunk into the ground, the ground is covered with an automatic cover, and the ground is level.

The electric control cabinet is on the ground and can be flexibly placed according to needs. The control cabinet is designed with an emergency stop button, which is used for emergency stop. The main power switch is equipped with a lock and is specially managed by a dedicated person to ensure the safety of the operation.

The support arm flip cover is a 3mm pattern steel plate and a square tube frame load-bearing structure, and the car can pass normally from above.

Both the mechanical lock unlocking mechanism and the cover turning mechanism are hydraulically driven, which are reliable in action and safe to use.

The hydraulic throttling device, within the maximum lifting weight set by the equipment, not only guarantees a faster ascent speed, but also ensures that the lift slowly descends in the event of mechanical lock failure, oil pipe bursting and other extreme conditions to avoid sudden rapid speed. The fall caused a safety accident.

The built-in rigid synchronization system ensures that the lifting movements of the two lifting posts are absolutely synchronized, and there is no leveling between the two posts after the equipment is debugged.

Equipped with the highest limit switch to prevent misoperation from causing the vehicle to rush to the top.

The equipment operating procedures are as follows

Press the “Ready” button to automatically complete the following preparations: the flip cover opens automatically – the support arm rises to a safe position – the flip cover closes – the support arm drops onto the cover and waits for the vehicle to drive in.

Drive the vehicle to be repaired into the lifting station, adjust the matching position of the supporting arm and the lifting point of the vehicle, and press the “drop lock” button to lock. Press the “up” button to lift the vehicle to the set height and start maintenance work.

After the maintenance is completed, press the “down” button, the vehicle will land on the ground, the support arms will be manually extended to keep the two support arms parallel to the front and rear directions of the vehicle, and the vehicle will leave the lifting station.

Press the “reset” button to automatically complete the following resetting tasks: the lift is raised to a safe position-the flip cover is opened-the arm is lowered in the flip cover mechanism-the flip cover is closed.

Technical Parameters

| Lifting capacity | 5000kg |

| Load sharing | max. 6:4 ior against drive-odirection |

| Max. Lifting height | 1750mm |

| Entire Lifting (Dropping)Time | 40-60sec |

| Supply voltage | AC380V/50Hz(Accept customization) |

| Power | 3 Kw |

| N.W. | 1920 kg |

| Post diameter | 195mm |

| Post thickness | 14mm |

| Capacity of oil tank | 16L |

Product detail pictures:

Related Product Guide:

Being supported by an highly developed and specialist IT team, we could give technical support on pre-sales & after-sales service for Manufacturer for Double Post Underground Lift - Double post inground lift series L5800(B) – Tonghe , The product will supply to all over the world, such as: Romania, Turkey, Saudi Arabia, We are committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional products and vast knowledge of technology makes us the preferred choice for our customers.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.